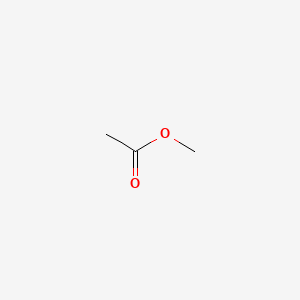

C 3 H 6 O 2. Methyl acetate is produced by esterifying methanol with acetic acid in the presence of an esterification catalyst and separating the products in the.

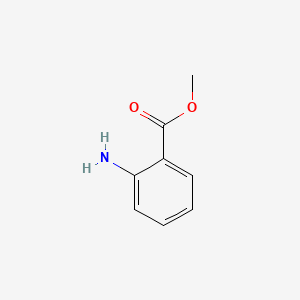

Methyl Anthranilate C8h9no2 Pubchem

The glacial acetic acid is reacted continuously with at least a stoichiometric amount of methanole in a reaction zone in the.

. Switch to calorie-based units. Also the direct use of MA in coatings metal industries plastics automobile industries printing solvents and dyes causes the accumulation of MA in the atmosphere through evaporation 8 9 10. Methyl chloroacetate C3H5ClO2 CID 7295 - structure chemical names physical and chemical properties classification patents literature biological activities safetyhazardstoxicity information supplier lists and more.

C 3 H 7 O 2 Molecular weight. Use as a Solvent. Methyl acetate can be made in a variety of ways some of them are listed below Carbonylation is one method that is utilized in industry.

The optimum conditions for synthesis of acetic anhydride by carbonylation of methyl acetate have been found. Methyl acetate is formed due to the interaction between a dimethyl ether molecule and an acetyl intermediate. Afterward the methoxide inter- mediate attacks a carbonyl group of the anhydride forming methyl acetate and the methylcarbonate ion Figure.

Methanol is burned with acetic acid in the presence of sulfuric acid to make methyl acetate. The acid catalyst used in this reaction was cone sulfuric acid. Ethyl acetate is less toxic than Methyl acetate.

Conversion of methyl acetate to acetic anhydride is approximately 75 and selectivity to anhydride is greater than 95. The methyl acetate reaction takes place at 175C 350 F and 26 bars 380 psig pressure. Methyl acetate is produced industrially by liquid phase reaction of acetic acid and methanol in presence of an acid catalyst.

Carbon monoxide substrates are brought together in these reactions. C 3 H 6 O 2. A reaction mechanism has been proposed for the carbonylation of methyl acetate with formation of acetic anhydride in the presence of a catalytic system consisting of rhodium III chloride zinc acetate and methyl iodide.

A variety of solid base catalysts were prepared by loading Cs 2 O over SiO 2 or Al 2 O 3 as the support materials. Formation of liquid methyl acetate- 3C s3H 2gO 2g CH 3COOCH 3l Δn g0134 Given- ΔH4429kJmol T2525273K298K As we know that ΔHΔUΔn gRT ΔUΔHΔn gRT ΔU44294831410 3298 ΔU442999245282kJmol Hence the standard internal energy of formation of liquid methyl acetate is 45282kJmol. In this process glacial acetic acid is reacted with methanol to form methyl acetate and glacial acetic acid is also used as an extractant for water and or methanol.

Process for the preparation of high purity methyl acetate at high reagent conversion rates. Methyl acetate MA is an important VOC that originates from degradation of methyl tert-butyl ether MTBE tert amyl ether TAME and ethyl tert-butyl ether ETBE. Copy Sheet of paper on top of another sheet.

The reaction is facilitated by the confinement effect characteristic of small zeolite pores in particular eight-membered pockets of mordenite. Methyl acetate is only occasionally used as a. The incorporation of CO into the methoxy group leads to the formation of an acetyl intermediate.

Acetic Anhydride by the Carbonylation Process. Methyl acetate is moderately toxic. Siirola 1996 is a classic application of process intensification PI where the conventional MeAc production process consisting of one reactor and nine distillation columns was replaced by a single RD column.

The melting point of ethyl acetate is -836C while the boiling point is 77C. Information on this page. The vapor-phase aldol condensation of methyl acetate MeOAC with formaldehyde HCHO to form methyl acrylate was investigated over solid base catalysts.

Methyl Acetate Surface Tension Coefficient Gradual Transition Acid Solutions Hydrocarbon Production Low Viscosity The object of research in this work is the intensification of hydrocarbon production. The most problematic task of the study is the efficiency of intensification of compacted high-temperature carbonate reservoirs. Empirical formula Hills system for organic substances.

Methyl acetate MeAc esterification process by Eastman Chemical Company Agreda et al 1990. Acetic acid methyl ester.

Isoprene Rule For The Construction Of Terpenes And Terpenoids

Methyl Acetate Ch3cooch3 Pubchem

Fructose Methyle Acetate Chemistry Math Pharmacy

What Smell Can I Get When Mixing Methanol With Acetic Ethanoic Acid Quora

Installing The Magic Methyl C H Methylation In Synthesis Chemical Society Reviews Rsc Publishing Doi 10 1039 D0cs00973c

Difference Between Methyl Acetate And Ethyl Acetate Compare The Difference Between Similar Terms

File Synthesis Of Methyl Acetate Svg Wikimedia Commons

Acid And Base Forms Of Methyl Red Download Scientific Diagram

The Reaction Of Aromatic Aldehyde Ethyl Methyl Acetoacetate And Download Scientific Diagram

Methyl Acetate Formula C3h6o2 Properties Uses Molar Mass Embibe

Mass Spectrum Of Methyl Ethanoate C3h6o2 Ch3cooch3 Fragmentation Pattern Of M Z M E Ions For Analysis

Stepwise Iodide Free Methanol Carbonylation Via Methyl Acetate Activation By Pincer Iridium Complexes Journal Of The American Chemical Society

Methyl Palmitate C17h34o2 Pubchem

File Synthesis Of Methyl Acetate Svg Wikimedia Commons

Methyl Acetate Formula C3h6o2 Properties Uses Molar Mass Embibe

Methyl Acetate Formula C3h6o2 Properties Uses Molar Mass Embibe